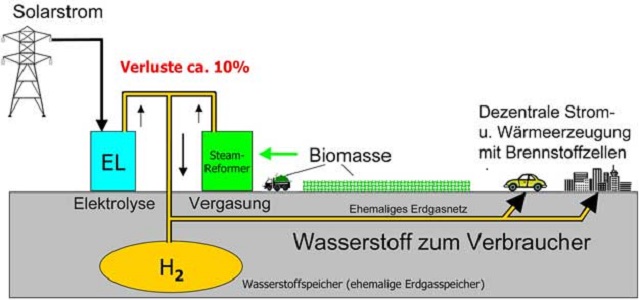

Local bidirectional electricity hydrogen economy

Requirement: every building has an electricity connection and H2 (Former gas grid) connection!

Known versions:

There are four different applications of bidirectional charging in the electricity sector:

Vehicle to Grid (V2G)

Vehicle to Home (V2H)

Vehicle to load (V2L)

Vehicle to building (V2B)

Overview

Bidirectional charging - when will the potential be exploited in Switzerland? | And when in Germany?

Further possibilities would be in the Green H2 Hydrogen area

Home H2 to Grid H2 (H2H-H2G) H2 produced locally via electrolysis - fed into the former natural gas grid H2 network

Grid H2 to Home H2 (H2G-H2H) H2 of the H2 grid is converted by means of (examples:) H2 fuel cell home power plant or into heat, electricity, (heat pump).

This would be a prerequisite to always have a BU possibility in case of power supply failure or H2 network failure.

Building area, actually with each Smart Meter!

A power surplus in the EE area wind, water, PV could be converted by smart meter electricity, in H2 by electrolysis.

If there is a shortage of electricity, electricity-gas could be fed in via the H2 fuel cell of the domestic power plant.

Parallel to this, H2 biomass power plants are being built to achieve the transition from natural gas to H2 as quickly as possible!

Costs: 50MW H2 power plant approx.: 50 million €

Costs: 500MW H2 power plant approx.: 120 million €

At port locations also 5 GW model possible approx. 500 million €.

From planning to commissioning approx.: 2 years.

Even faster if the application documents are processed quickly!

EUROPEAN PARLIAMRNT Brussels 10th of January 2007

Forum Bioenergy of SOLARPRAXIS on 8 and 9 Dec. 2005 in Berlin

Synergy of solar power and a hydrogen economy

Publications for download

And now everybody asks: Gas grid ready for H2 - Answer:

Naturalhy Brochure 2007

Europe's Local Hydrogen Networks 13.12.2021

ready4h PART 2: The value of local hydrogen distribution networks in a decarbonised Europ2

Converting gas networks to hydrogen reduces climate costs

In the L-gas areas, do not switch to H-gas but to H2 right away

Maybe I have forgotten something in my considerations?

Please let me know via contact.

H2per electrolysis price 12 ct./kWh too expensive!and the general public is deprived of green electricity.coal-fired power plants must remain on the grid longerH2from bio-waste always available price 3 ct./kWh and CO2 can be used in e-Fuels

Publications of Karl-Heinz Tetzlaff

For biohydrogen from cascaded conversation it is assumed that about 5% of the carbon in the biomass is not converted but is discharged with the ash and returned to the field. This 5% is about 25 kg of carbon per ton of biomass ( 50 MW power plant 10 tons of biomass per hour) absolutely dry. With 110 kg of H2 production per ton of dry biomass, this is approx. 223 g of carbon per kg of hydrogen, i.e. a good 800 g of CO2 that are permanently fixed. If CO2 is also injected into salt aquifers, the total amount of carbon saved per kg of hydrogen is 4.5 kg, or 110 g of carbon or 423 g of CO2 per kWh. With the current electricity mix of approx. 500 g CO2 per kWh, 42.5 g per kWh would have to be deducted for the required electricity, i.e. a negative footprint of 380.5 g per kWh or a CO2 footprint of 22.5 g/kWh for coke alone. Electrolysis hydrogen would have a CO2 footprint of 714 g/kWh, but is valued at 0 g or at most at 10 g wind or 5.7 g hydropower, hydrogen from natural gas comes to between 210 g and 260 g.

The production of H2 from Biomass/waste Price 3 ct./kWh with 900g CO2 reduction per kg Hydrogen should be hard to beat - WITHOUT NEEDING GREEN POWER!

All this is already known to the EUROPEAN PARLIAMRNT Brüssels 10th of January 2007 - but nothing happened

June 2024:

Heating/combustion of H2 NO! Fuel cell->approx.50%heat+approx.50%electricity->heat pump-JAZ4.5 1 kWh H2= 500 watt hours heat+ 500 watt hours electricity, heat pump= 4.5*500= 2250 watt hours heat or 500 watt hours electricity feed-in