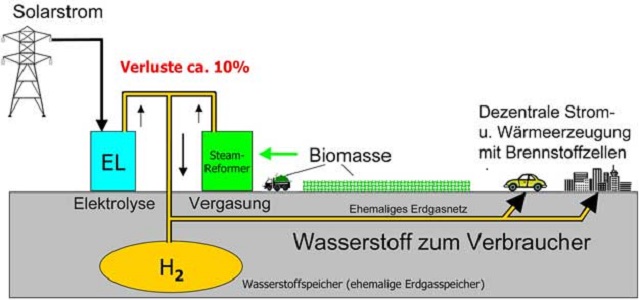

Some green hydrogen production methods

For example, hydrogen from "green electricity" via electrolysis, which arises from biomass in biogas plants, biomass power plants or from "co-fireing" in coal-fired power plants, is "green hydrogen".

Hydrogen, produced directly from biomass, is only "gray" or at best "turquoise hydrogen". Exactly the same biomass could be used for this; only with a significantly higher degree of efficiency based on the hydrogen yield.

Since the CO2 can also be captured in these processes, i.e. CCS becomes possible, it is the only method I know of to remove additional CO2 from the atmosphere.

It is incomprehensible that an H2 production process in which CO2 can be actively broken down and which at the same time entails significantly lower production costs is so misunderstood.

(Electrolysis today approx. 12 ct / kWh H2 or bio-hydrogen using the pressurized fluidized bed gasification process approx. 3 ct / kWh H2)

There are already companies and institutes that offer the relevant technologies on the market and others that are working on or have researched the relevant technologies.

Examples: DLR with the sponge iron process - sun tower in Spain, KIT with both entrained flow gasification and gasification in "supercritical water", H2-Patent GmbH process in fluidized bed gasifier, Plagazzi gasification of garbage and biomass to hydrogen, Graforce hydro-plasmolysis of biomass in wastewater, hydrogen directly via blue-green algae, hydrogen directly via PV modules with suitable catalysts, bio-batteries from Fraunhofer UMSICHT Sulzbach Rosenberg, etc.

Shutting down fossil power plants and the associated reduction in CO2 are certainly possible earlier using these technologies. Even if only part of the required energy can be provided through this process.

As of today we are unfortunately still a long way from a 100% supply with "green electricity". The production of H2 via electrolysis is certainly a viable option when there is an oversupply of "green electricity".

At all other times, “green electricity” is withheld from citizens and the need to continue operating fossil-fuel power plants is promoted.

What is the reason that several billion euros are invested in funding for H2 electrolysis applications and not a euro for the production of H2 from biomass and biogenic waste?

I am also moved by the question of why only electrolysis is published? Do interest groups want to influence public relations through this information policy?

From a macroeconomic perspective, the energy turnaround should not only be carried out quickly but, if possible, also inexpensively. This is the only way to maintain social prosperity and at the same time strengthen competitiveness on international markets.

Klaus Hesse

For biohydrogen from cascaded conversation it is assumed that about 5% of the carbon in the biomass is not converted but is discharged with the ash and returned to the field. This 5% is about 25 kg of carbon per ton of biomass ( 50 MW power plant 10 tons of biomass per hour) absolutely dry. With 110 kg of H2 production per ton of dry biomass, this is approx. 223 g of carbon per kg of hydrogen, i.e. a good 800 g of CO2 that are permanently fixed. If CO2 is also injected into salt aquifers, the total amount of carbon saved per kg of hydrogen is 4.5 kg, or 110 g of carbon or 423 g of CO2 per kWh. With the current electricity mix of approx. 500 g CO2 per kWh, 42.5 g per kWh would have to be deducted for the required electricity, i.e. a negative footprint of 380.5 g per kWh or a CO2 footprint of 22.5 g/kWh for coke alone. Electrolysis hydrogen would have a CO2 footprint of 714 g/kWh, but is valued at 0 g or at most at 10 g wind or 5.7 g hydropower, hydrogen from natural gas comes to between 210 g and 260 g.

The production of H2 from Biomass/waste Price 3 ct./kWh and with 900g CO2 reduction per kg Hydrogen should hardly be surpassed!

All this is already known to the EUROPEAN PARLIAMRNT Brüssels 10th of January 2007 - but nothing happened